CNC machine type

The normal materials utilized in building CNC machines are aluminum, polymer composite, and iron cast. The iron cast is the best form when you want a solid machine for difficult tasks. Different materials are appropriate for lighter assignments. Your CNC machine ought to be bigger than the most extreme region for your items. Your machine should have a span greater than the biggest material you cut. It decides the rate you can cut materials during the assembling process.

Like some other machines, a CNC machine might separate or wear out with use. You ought to guarantee that your experts can undoubtedly fix the brand that you buy and that the extra parts are accessible. This will diminish machine margin time. Contingent upon the machine you pick, you might have to expand the power accessible in the studio. Checking the power prerequisites of your gadget and making the important changes at work is fundamental.

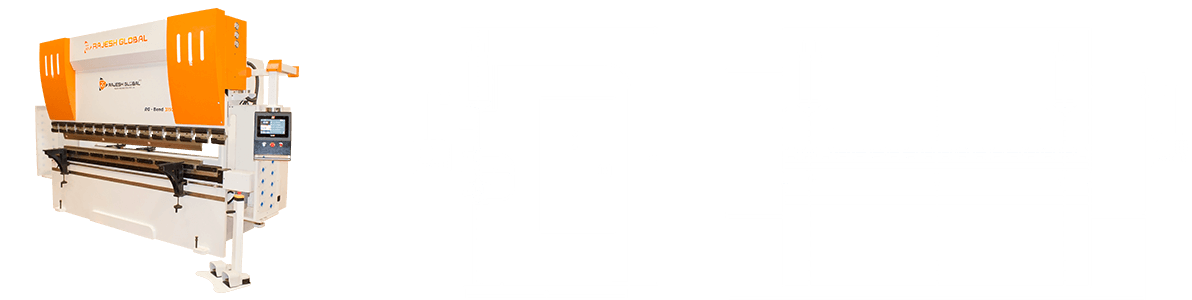

Pressing machines are also known as forming presses. A machine press is a tool used in the manufacturing industry to deform/shape a workpiece under high pressure. There are different types of machine presses, including cabinet presses, frame presses, solid surface presses, composite presses, multi-daylight presses, cold presses, rubber presses, recycling presses, and much more. The defining characteristic of all machine presses is that they press a workpiece using high pressure to change its shape. Hydraulic Press Brake manufacturers

H-Frame presses this will dictate how much force is required to perform the pressing operation. Always increase the tonnage required. This prevents premature wear of continually using the press at its maximum capacity, meaning less wear and tear on both machine and operator not having to push the limits on every part.

CNC and brake press?

Since workers aren’t holding the sheet metal when using a CNC folder, they can’t adjust angles as easily. Workers that use a press brake can bend the sheet metal as they see fit. Since they have more diversified bending capabilities, press brakes are more efficient than CNC folders.

Stamping Press

Another common type of machine press is the stamping press. Stamping presses are similar to punch presses, with both types of machine presses using a pressurized tool to manipulate a workpiece. Stamping presses, however, don’t actually create clean or complete holes. They simply deform the workpiece so that it takes the shape of the die with which it’s pressed. The workpiece is secured to the stamping press’s bolster plate, at which point it’s sandwiched between a press tool and a die. The stamping press pushes the tool onto the workpiece, thereby forcing the workpiece to take the shape of the underlying die. Visit NC Press Brake machine manufacturers

The Machine Press

Prior to the invention of the machine press, workers were required to manually hammer metal by hand to change its shape. Not only was this physically taxing, but it was also ineffective when performed on hard and strong metals. During the industrial revolution machines started to be developed that would take over and replace most manual labourers. These machines were able to use greater forces as well as work more efficiently.

The original presses were powered by steam, where as today’s machines are powered by hydraulics run on electricity.

Machine presses rely on high pressure to perform their intended applications. Heavy duty presses use around 1 to 30 tons of pressure. As a result, they are able to reshape most materials, including bronze, copper, aluminium, iron, steel, wood and composites. The high pressure of a press squashes even the hardest metals, allowing manufacturing companies to reshape wood or metal work-pieces into their desired shape.

Machine Presses Work

While the exact mechanics vary depending on the type of machine press, most machine presses work by pressing a plate or die onto or against a workpiece. The workpiece can either be manually placed into the machine or a through-feed will automatically place the workpiece in the correct position. Once in position, using hydraulics pressure, the machine press pushes the plate or die against the surface of the workpiece, which causes the workpiece’s shape to deform into the shape required by the manufacturer.

What are the parts of a press brake?

A press brake has three basic parts, the ram or top tool, the bottom tool, and the mechanism that drives the ram. The main operation of all press brakes is the same, however, how the ram is used to exert force and shape the part can differ in different types of press brakes.

Automated Press Lines

Automated press lines are designed in conjunction with all through-feed press options to be fully automatic or semi-automatic. They can start at the brushing stage where the material is cleaned, through to gluing, pressing then cutting.

What is the bending speed of a press brake?

Characteristics that define press-brake capabilities include pressure or tonnage, working length, distance to the backgauge, work height, and stroke. The speed at which the upper beam operates usually ranges from 1 to 15 mm/sec

Can a press brake cut?

A press brake is a machine that performs multiple functions, including cutting, blanking, punching, and more. Many industries have utilized this equipment to produce customised and OEM-designed parts from sheet metal.

What are brake system and their functions?

A brake system helps to stop vehicles within the smallest possible distance. This is achieved by converting the kinetic energy of the vehicle into heat energy. It also functions on a mechanical device where motion occurs, the brake is applied to stop it within a short period of time.

How much pressure is in a hydraulic brake system?

Typically the hydraulic pressure generated during light to normal braking will be from 300psi to 500psi. Panic braking is generally considered to start at about 600psi. The proportioning valve will start to limit pressure to the rear brakes at this time.

What control system is used in CNC?

A CNC system requires motor drives to control both the position and the velocity of machine axes. Each axis must be driven separately and must follow the command signal generated by the numerical control. There are two ways to activate the servo drives; the open-loop system and the closed-loop system. There is an all-inclusive issue of keeping a constant flow of machine administrators as old-school mechanical engineers begin to leave the labor force, alongside ensuring current administrators can stay aware of the capacities of present-day CNC machines.

Current machines

The manner in which current machines are moving as of now implies that they present issues and instructional exercises to the administrator, permitting them to work all the more with certainty and commit fewer errors since they can decipher the signs the machine is giving. This means the innovation isn’t yet where CNC setters or CNC administrators can be completely supplanted thus these positions are still sought after. A knowledgeable CNC administrator is a crucial gear-tooth in the outcome of a machine shop and we are continuously searching for CNC Mill operators and CNC Turners to join our clients.

What are 2 examples of Pascal’s principle?

Examples of Pascal’s principle applications include hydraulic crane, hydraulic lift, hydraulic jack, and hydraulic brake system. An excavator digging a hole, a car being lifted by a hydraulic lift, and even squeezing a toothpaste tube applies Pascal’s principle.

CNC machine administrators work in a wide assortment of fields. Individuals from all kinds of pursuits, for example, specialists and, surprisingly, military gatherings, exploit the expensive investment funds accumulated by utilizing CNC machines to transform unrefined substances into eventual outcomes. The machines are quicker, more proficient, and more secure, as well.

CNC Machine

Computer Numerical Control machines are robotized machines, which are worked by computers executing pre-customized arrangements of controlled orders. CNC machines are basically something contrary to “old-school” gadgets that are physically controlled by hand wheels or switches, or precisely mechanized by cams alone. The present current CNC machines comprehend and work utilizing CNC machining language – called G-code – which lets them know exact estimations for creation, similar to taking care of rate, speed, area, and coordination.

The present plan and mechanical parts for CNC frameworks are exceptionally computerized – in contrast to the old, perilous, production line machines you’d consider once upon a time. The parts’ mechanical aspects are characterized by utilizing computer-helped plan programming and afterward converted into assembling mandates by computer-supported assembling (CAM) programming. Accordingly, it is fundamental to have proficient CNC mechanics and software engineers to work on this innovative machinery.

How this affects CNC Experts

Sounds perfect, correct? In the event that you are an office chief or creation manager, it most likely does. However, in the event that you are a CNC setter, CNC administrator, or CNC developer, you may be considering how this affects your capacity to get and hold down CNC occupations into what’s in store. The possibility of numerous parts of your job becoming mechanized may appear to be startling, however, there are silver linings. With innovation pushing CNC machining forward, producers can take on additional orders, and that implies growing their activities.

The fundamentals of CNC machine programming

There are three essential CNC machine programming strategies — manual, conversational, and CAM framework programming. With manual programming, the administrator inputs code physically, which can be tedious and to some degree drawn-out. It likewise requires cozy information on the programming language. In any case, manual programming is a significant primary range of abilities to have close by, and it’s a successful method for making speedy changes to CAM yields and enhancing code.

Any manual programming

Conversational or “shop-floor” programming is an inexorably well-known strategy that includes realistic and menu-driven capabilities. Administrators input orders straightforwardly into the CNC machine, very much like in manual programming, which lightens potential issues that might emerge from unfortunate post-processors in CAM. CAM framework programming is like the conversational technique yet further developed. With a CAM framework, the product gives a high-level GUI instrument way methodologies to help the administrator get ready and create the program — disposing of the requirement for any manual programming — and moving it straightforwardly to the CNC machine.

These machine programming strategies include G-code and M-code. G-code is the programming language that teaches the machine what to do, working with exact and repeatable parts. M-code controls all of the different CNC machine capabilities, for example, shaft revolution start and stop. M-codes are adaptable and shift by machine, so administrators and developers should twofold check they’re contributing the right capabilities before they begin machining.

Utilization of CNC Machine:

CNC machines are utilized in pretty much every assembling industry. With expanding requests in the assembling business, the utilization of CNC has likewise expanded. The machine devices that accompany CNC are machines, factories, shapers, welding, and so forth. Pretty much every assembling industry utilizes CNC machines. With the cutthroat climate and expanding requests, the interest in CNC use has expanded significantly. The machine devices that accompany CNC are Machines, Factories, shapers, Welding, and so on. The businesses utilizing CNC machines are the car business, metal evacuation industry, metal framing industry, electrical release machining industry, wood industry, and so on.

What is the utilization of CNC in the business?

CNC machines are likewise utilized in the assembling business for delivering rectangular, square, adjusted, and, surprisingly, strung positions. These machines have some control over and do all cycles, including processing, crushing, turning, exhausting, and reaming, among others, utilizing explicit machine apparatuses for each undertaking.

Disadvantages of CNC Machines

They are expensive. A prepared administrator is expected to work the machine. In the event of a breakdown, a profoundly talented expert is expected to take care of the issue. A decrease in physical work can prompt joblessness. Its establishment cost is high.

The Future of CNC Machining

CNC machining fundamentally affects the improvement of numerous items we use in our day-to-day routines and is continually advancing through recent trends and advancements.

Instructions to Choose the Best CNC Machine Type

The best CNC machine type is chosen by understanding what CNC process you need to utilize and what materials you are working with. A few key contemplations are the machine’s weight, the functioning span, the machine’s speed, the accessibility of extra parts, and power utilization.

Behind The Scenes: The Life Of A Model In Dubai Modeling Agency