Puffy Foam is often wont to reach 3D-like embroidery. it’s extremely popular commercially for logos on caps and backpacks, however as you’ll be able to see within the liliaceous plant style I created for this text, you’ll be able to embroider it during a ornamental machine to administer your style an additional dimension.

Digitizing for puffy foam may be a touch a lot of technical than your daily digitizing, however if you create certain you follow some rules, it’s not very that sophisticated. this will be done simply with Hatch Embroidery data converter.

What is Puff or 3D embroidery?

Puff or 3D embroidery is AN embroidery method within which we tend to add a chunk of froth that’s placed underneath the embroidery so it may be upraised or 3D created AN look. it’s referred to as Puff or 3D embroidery. Puff or 3D embroidery works best on a hat or are may be used for article of clothing like jackets that aren’t washed often.

This is not sometimes the case suggested for a garment that may be washed ofttimes or placed during a drier. it’s additionally not suggested for garments that square measure clean. this can cause the froth to crumble throughout the drying method or cleansing processes thanks to the chemicals used.

Which type of froth to use?

There square measure several foam product on the market however you have got to use caution wherever does one get them? they need two millimeter, 3 mm, and four millimeter foam. i take advantage of a 3mm product. i buy the simplest results from it and it offers American state the high loft that i would like and my customers have continually been terribly pleased with it. Embroidery offer distributor, not craft store. Your foam ought to be designed for embroidery. This foam is incredibly completely different and can react otherwise. And also know about sublimation printing.

I get my foam at SM Crystal in Buffalo, NY. They sell it in one-color packages and multi-color packages therefore you have got a range of basic colors in hand.

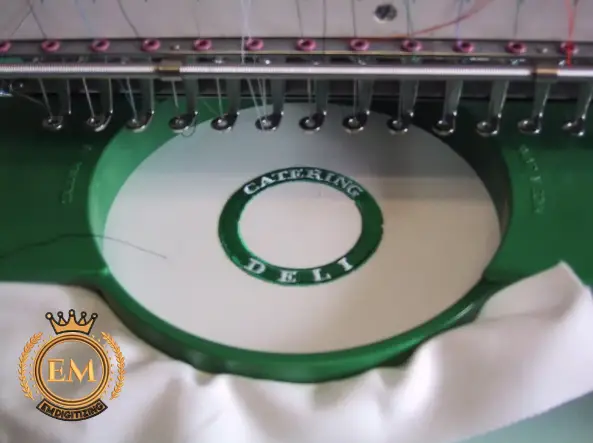

How do I sew a puff / 3D embroidery design?

The process of embroidering with puffy fonts, logos, and styles could be a bit completely different from regular embroidery, however no more tough. 1st of all, recognize that exploitation 3D Puff has a lot of value and a lot of stitches within the style. It’s as straightforward as sewing:

- Sew all of your flat embroidery 1st.

- Make a stop within the machine when your last flat piece

- Place the puff on the world you would like to stitch and restart the machine.

- Sew a border around your puff space.

- Remove excess puff material

- Complete the look and clear the surplus puff foam material.

Some basic tips to induce started with 3D embroidery:

Digitizing is very important. you may got to apply long stitches to fill the house that the froth is taking. we tend to suggest exploitation code like Puffy Fonts to alter yourself. There is also some trial and error during this a part of the look, therefore take it slow to check.

Learn how to program stops on your machine. you must be able to stop when a definite color modification.

Keep the froth down and use tape or sticky school spray to stay it in situ. Once the primary stitches have gone into the froth, you don’t need to worry concerning moving on.

Foam works best on styles with sensible underlay borders and cloth stitches across the froth. Note that no style may be exhausted foam. for instance, serious filling stitches or too several underlays on the froth might not offer the specified form.

Using a sharp needle will facilitate pack up the froth. confirm to use the backing that you just sometimes do on a style. this kind of embroidery needs support to stabilize.

Stabilizer Used for 3D Embroidery

If you’re embroidering 3D foam on hats, i’d counsel employing a tear o stabilizer. Since it’s a cap and doesn’t have abundant flexibility, the stabilizer is that the best to tear (hence the name). Hats are not sometimes washed abundant, that helps within the longevity of the froth. The less you wash, the longer the froth can last.

If you’re exploitation 3D foam on something wearable, I’d suggest employing a cutaway mesh. As I continually say, “If you wear it, don’t tear it.” I won’t use a show mesh, therefore you don’t see it through article of clothing.

How to produce Puff or 3D Embroidery

- Run the regular decorated components 1st – With the “foam” style, you would like to run the regular decorated components 1st. All embroidery inheritance styles square measure designed with this in mind.

- Stop the machine – Once all the regular embroidery colors square measure done, your coloring info sheet can offer you the steered color of the thread then the word “foam”. Upon reaching this color modification, the look ought to move to the highest of the look, and you must stop your machine.

- Lay the froth – At this time, you may place the froth within the areas wherever the embroidery are going to be done. (Always making an attempt best to use an equivalent colors of thread and foam whenever possible).

- Sew take-down stitches – the primary stitches on all-time low square measure “take-down” stitches to secure the froth within the cloth.

- Continue stitching – then, the look can proceed to get rid of all areas of the froth.

- Remove the froth – currently that you just square measure able to take away the froth, it ought to be simply torn with styles that are properly digitized.

- Done! – currently you recognize the way to do foam embroidery.

Step By Step the way to change Puff or 3D Embroidery

Step 1:

Digitize the regular decorated components of the primary style, inserting the stuffed areas and white letters down as you usually would. Once you’ve eliminated these components, program a stop at the highest of your embroidery field. this permits you to stay the froth down whereas the stitching head is out of the approach. If you put in force making an attempt to form ready-made hats, you may program your stop towards the highest of the hat, therefore there’s no thanks to sew heads.

Step 2:

Before golf stroke the froth down, provides it a fast shot of adhesive spray to cut back movement once managing all-time low. keep in mind foam comes in several colors. try and match the colors of your foam and thread as closely as attainable.

Step 3:

Using manual sewing, i’d sometimes block the look from the within out. With relevance the “Zeyda’s” emblem, I did a manual sew on the “d” and “s” to stabilize. So the froth components before really beginning the “Z”.

Step 4:

Once you have got lowered the “Z”, you would like to fastidiously place. The underlay concerning .2 millimeter removed from the outer column. So the worth of the underlay ought to be set to one millimeter. This can facilitate to drill the froth before the column seam goes down.

Step 5:

With foam, you not solely need to worry concerning the bottom column. However you furthermore may need to “cut” the ends of your columns. This can offer you a neat and clean cut after you take away the froth. You want to change your “end” before beginning your column.

Step 6:

Density is that the key to improvement foam. Everyone’s code is slightly completely different from the language values, therefore I’ll try and solve it in share terms. If your traditional price was 100%, the froth would need 50-40% density, double the quantity of stitches usually needed.

Step 7:

Repeat these steps for every letter or part till all of your foam square measures are complete. As you’ll be able to see, there square measure more steps, and it’s vital to follow. The underlay and therefore the columns properly. Digitizing alone is a lot of toilsome than regular digitizing. Then don’t mind your piece of writing session.

Conclusion

Using puffy embroidery foam could be a good way to market your stitches. Giving your style a 3D result and feel. once exploitation 3D foam embroidery styles. Keep in mind to use a clearly digitized style for this use. To confirm the security of your machine and attire.