Any type of construction work involves the use of materials that have certain quality characteristics. You can not do on a construction site without concrete and cement mortar. But where they find their application and what is the difference between concrete and cement mortar, we will now find out concrete molds.

The correct proportions of this solution will determine the quality and strength of the final design. The key component element of concrete is cement – a mineral substance in the form of powder, which performs the main binding function. After joining with the liquid, it turns into a viscous mass. After solidification, the concrete mixture becomes homogeneous in structure, solid and strong.

Cement mortar, unlike the previous building material, consists of only three components: cement, sand and a liquid that serves as an activator. Depending on what characteristics the finished mixture should have, it may include specialized additives and plasticizers. Due to the inclusion of these elements in the solution, the level of water resistance, strength, resistance to temperature changes and external influences, as well as other technical characteristics, increases. There are a huge number of varieties of both cements and concretes on the modern market.

CONCRETE AND CEMENT MORTAR – WHAT IS IT?

Concrete is a stone created by man. Mixing of four components-cement, fillers (crushed stone, construction sand) and water. Concrete is a composite material-the result of molding and hardening. The main component is cement of a certain brand, thanks to the cement, the mixture after hardening acquires properties that are not much inferior to natural stone. Cement mortar-does not contain a large filler, has three components in the composition-water, cement and sand. The cement mortar is greatly influenced by additives and plasticizers that are introduced into the mixture during mixing. Additives increase the quality characteristics of the frozen solution – water resistance, resistance to freezing, additional strength, etc. Concrete and cement mortars have a fairly impressive classification.

The main difference between concrete and cement mortar is that concrete contains a large aggregate-gravel or crushed stone. But the cement mortar contains only construction sand as a filler. This leads to another difference – the use of building mixes.

Total:

1. Concrete consists of 4 components-cement, coarse filler, sand and water. The solution consists of 3x-cement, water and sand.

2. Large and medium-sized parts of load-bearing structures are constructed from concrete, cement mortars are used for filling joints, bricklaying, and surface treatment.

Varieties by composition

According to their composition, such solutions are divided into:

1) Cement-based. Sand is mixed with cement in a ratio of 3: 1, then all this is mixed with water. The shelf life of such a composition is no more than an hour. It is not particularly plastic, however, the level of strength deserves praise.

2) Calcareous. In the same proportions – 3:1 – sand is mixed with lime. For the fastest hardening, gypsum is mixed with the main composition of the solution. But this significantly reduces the working life of such a mixture. You can only work with it for a few minutes. It is used during the laying of walls to fasten concrete blocks or bricks. Cement-lime.

Here, the cement is not diluted with water, but with diluted liquid lime. This mixture has increased strength, is very plastic, and is easy to work with. Often, this composition is used to finish the floor covering, walls and ceilings.

The presence of mineral impurities and their advantages. Experienced craftsmen often add mineral impurities to the cement:

1) silica;

2) small slag pellets;

3) fly ash;

4) limestone. These impurities greatly improve the quality of the mixture. Cement grades CEM III, CE IV, CEM V have a lot of mineral impurities in their composition.

In CU II cement mortars, only 20% of such additives are present, and CEM I does not have them at all. These impurities add plasticity to the material, fast solidification, significantly increase the service life of the finished product, and provide it with resistance to various destructive environmental influences.

Characteristic differences of concrete. Main components

The main components of concrete. Thanks to the added water, the concrete composite is able to transform from a loose substance into a solidified stone. In concrete, cement is the main binding component that guarantees fast bonding and hardening. This building material is used in the construction of massive load-bearing buildings. This is how it differs from cement mortar. The main components of the concrete composite are:

1) cement;

2) sand;

3) gravel as a filler. It is better to use certain types of cement.

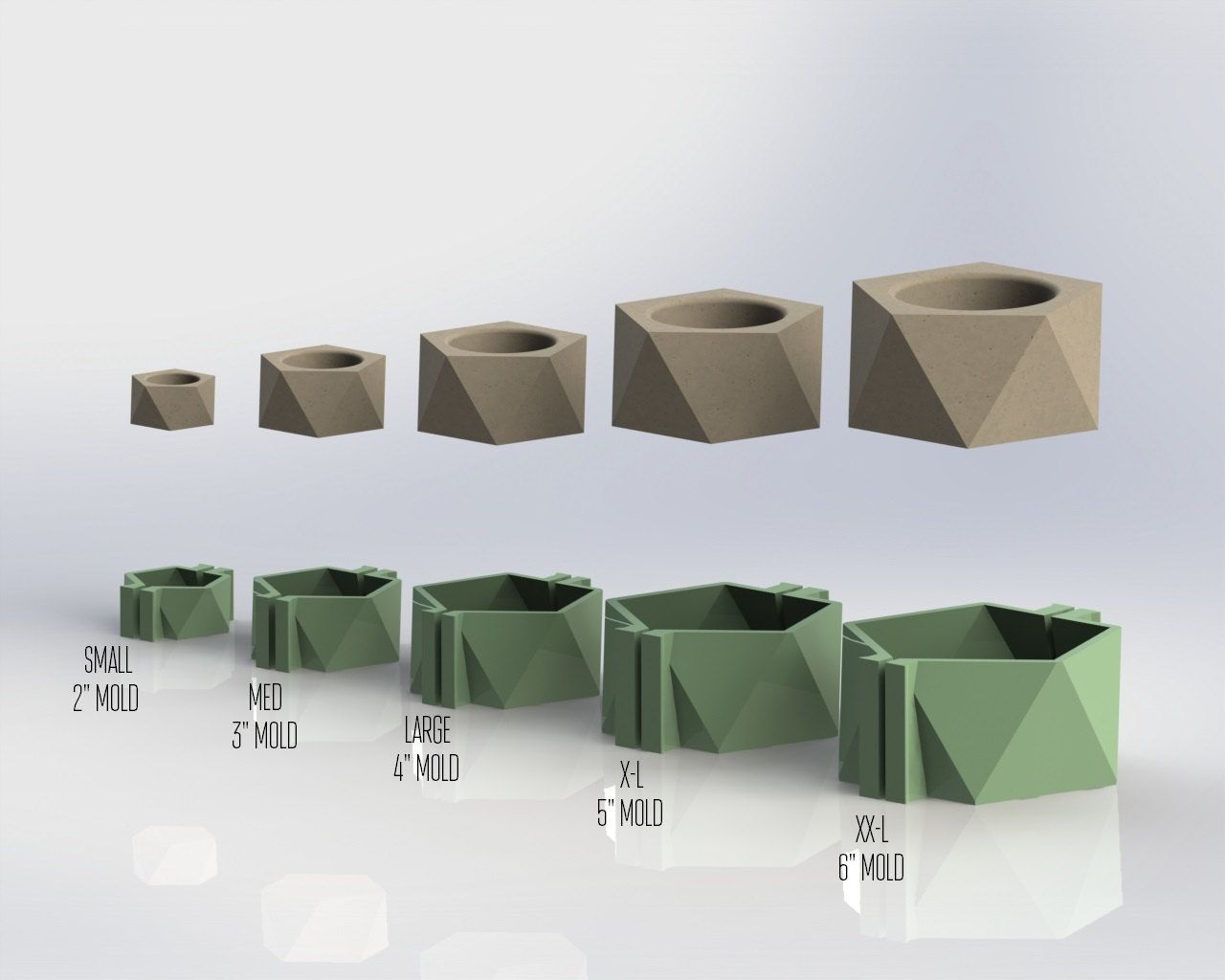

Video demonstration for creating types and molds of distinctive designs for concrete countertops.

As you’ll be able to see within the image, you can use a standard bowl for soups, muesli, etc. to pour concrete right into a mould.

If you wish to make a hemisphere, merely pour the concrete right into a bowl and press a smaller bowl centered into the concrete. This gives you a strong, hollow hemisphere after the concrete has hardened. So you’ve the likelihood to provide a “concrete bottle” by pouring the constructing material right into a glass bottle and carefully knocking it off after hardening.

Cement pavers, for example, look nice and are available a variety of styles and sizes to be able to tremendously improve the general look of your yard or garden. The draw back to these pre-made pavers, nevertheless, is that they’re quite expensive, and will add up very quickly if you have to purchase a big and even reasonable number of stones.

Silicone moulds are of course the most effective, additionally as a result of they can be utilized many times.

It is subsequently well worth the effort to produce a silicone mould yourself.

If you could have made a plaster mould of this or that object, of a physique half or something else, use it for the building material manufactured from sand, cement and water. In addition, you can even use everyday objects and perhaps not at first glance intended objects to make casting moulds for concrete. In this information we’ve summarised a number of possibilities, ideas and tricks that may allow you to to make your own concrete casting mould. From fencing system molds together with vibrating tables, Doser to concrete mixers, Armcon Molds USA are at the leading edge of design and growth in the precast concrete business.

You can also work with a company that has specialised equipment for making customized molds.

These controlled foam carving systems allow you to create anything you’ll be able to imagine. Remember that you all the time have to think when it comes to a unfavorable to get your constructive countertop to prove the way in which you envision it. Countertop makers mould these sinks either with their very own custom-made molds or with bought molds.

What the molds have in common is that they must be easy and waterproof and able to hold the concrete in place till it sets. Materials that meet those necessities embody fiberglass, Plexiglas, rubber, and polystyrene. Pouring concrete into type to creatively create decoration just isn’t only a welcome change from business ornament for house, office and garden, but also ideal to create a pastime. If you course of something with your personal palms, you’ll be able to stay out your creativity and provides your head one thing to do. And in addition, gifts are created for the household and their home, office or backyard. Whether with or with out video steerage from YouTube – attempt it out and work in popular DIY trend to make concrete figures, concrete furnishings and extra.

In this text, you’ll be taught slightly about countertop molds and somewhat more about sink mildew and countertop mold inserts. For an in depth rationalization of how to make a countertop mould, get a copy of Fu-Tung Cheng’s guide, Concrete Countertop Book. We hope you can implement great and creative concrete ideas thanks to our tips, tips and recommendations.

Hand crafted with premium supplies like full-grain leather and waxed canvas.

We manufacture custom steel moulds for industrial and construction functions. If you might be pleased to work on your project slowly and somewhat bit at a time, then having the ability to produce pavers at a time might be sufficient. If you disable this cookie, we won’t be able to save your preferences. This signifies that each time you visit this website you’ll need to allow or disable cookies once more.

Packages might embody fundamental precast moulds as well as technical/manufacturing coaching at a price. Financial help can be arranged with main banking establishments. We make ABS Concrete molds from 1/16″ up to 1/four” the thickest material used by anybody, simply starting out or for the Pro. You can get custom molds from a lot of the companies which have manufactured molds or you can make your personal utilizing liquid rubber.