We have already managed to forget the times when printing was possible only on a limited group of materials . It would seem that only 20 years ago technology appeared UV printing, . but already so tightly she entered our life.

What is UV printing used for?

With this technology, the highest quality images can be applied to almost any surface. Fewer people are asking about the possibility of offset printing, . preferring vibrant digital printing.

UV printing

It is base on the use of UV-curable inks. Thanks to this, images can be apply to paper, fabric, glass, plastic and even wood. Of the equipment using this technology, inkjet printers are still use,. but this time the ink does not penetrate into the materials, . but remains a thin and very durable layer on the surface. The ink is cure by irradiating the image with ultraviolet lamps. Before printing, the surface must be thoroughly clean of dirt and grease, . otherwise the image will lose its strength and durability.

The first printers to work with curing inks rely on special lamps. However, this technology was quickly supplant by LEDs . that produce beams in the same spectral range. So the service life of the equipment before replacing the lighting system . increased to 100 thousand hours instead of the previous one and a half thousand. Imagine how much cheaper production of large format advertising materials. has become with the new technology! So the speed of preparation of print runs increase and . ultraviolet printing became an integral . part of the life of any large and medium-size printing house.

Types of UV printing equipment

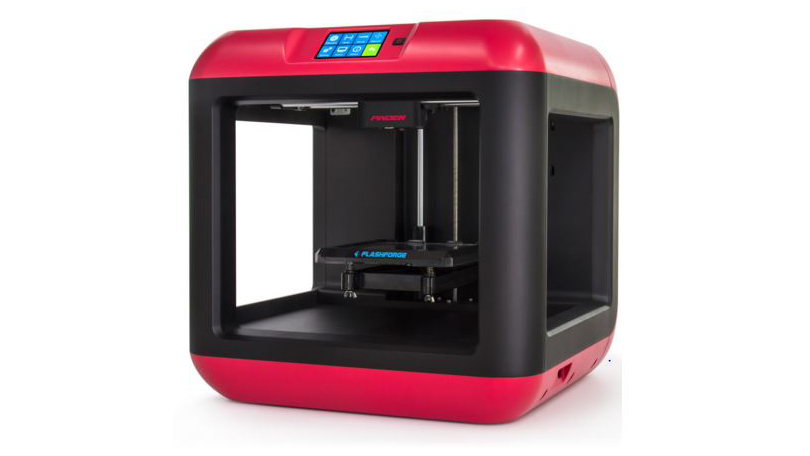

As we mention earlier, UV printing technology is impossible. without the use of UV printers. However, there are different types of this kind of equipment, . design for different types of materials, and therefore different purposes. So, the types of UV printers:

- Roll – the most familiar and simple technology use to roll material,. which is understandable by name. Printing is apply to backlit, banner fabrics, mesh films and of course paper. Base on the simplicity of the technology,. it also has competitors in the form of plotters (solvent and eco-solvent).

- Flatb – according to their purpose, they can be oppose to the previous type,. since the technology is base on printing advertising products on sheets . (tablets) of materials: plastic, foam board, corrugate board, glass, wood. What is a UV flat printer made of?

- Material fixation table;

- The so-call print head . In fact, it is thanks to this technology of the moving printing element tha . large and even very large objects can get an image on their surface, for example, a cabinet door, a mirror or a glass case.

- Hybrid or combine – and again everything is simple and logical: here . we are talking about a technology that allows you to work. simultaneously with rolls and sheets of materials. The only exceptions are materials that are too heavy. Such versatility becomes possible only due to the special design of the table, . which operates on the principle of vacuum clamping. For flat materials, additional tables with rollers are require for additional . movement of the roll material under the print carriage.

Benefits of UV printing

We believe that the advantages of UV printing lie on the surface and are understandable, . even after a brief description of the equipment and technologies use. However, a well-form list of benefits will not hurt.

So… Whatever the negative effects of the environment – high humidity, . sudden changes in temperature, chemical exposure – . all this does not affect the stability of the image. It will still please the eye for many years. All this is due to the polymerization of the paint with ultraviolet light, . which allows them to completely renew their structure.

Shorter production cycle.

Compare to offset printing, UV technology allows you to prepare . the ENTIRE print run on the same day the print studio receive the order. Miracles, isn’t it? Although in fact, referring here again to the technology, . the polymerization time of images in UV printing is many times . faster than when curing the results of offset, . which, in principle, is comparable to digital printing.

Photo ink is a distinct advantage of this technology. Thanks to the one-component pigmentation, . the ink hardens in seconds and does not harden on the . printheads in the form of lumps or films, interfering with subsequent printing. The printer is always ready to use!

Without marriage. (Almost). It is almost impossible to imagine a situation in which ink on the . can smear and spoil the drawing in any way.

Without smell. Some people certainly like the chemical smells of paints, but this is definitely . not an option for people with allergies and other ailments. Moreover, polymerization changes the structure of the ink, . making it safe for allergy sufferers and establishing . UV printing as one of the most environmentally friendly printing methods, . perfect for any interior and any advertising product, both indoors and outdoors.

Yes, white! White ink, which can be use for UV printing, creates images on transparent or dark . materials, adding contrast to the product.

Basis for printing. White ink can also serve as the basis for pictures on black items. Virtually any image can be apply over a dense white background, . making it even brighter and more durable. And of course, this is the technology use to create 3D images, reliefs and textures.

Durability and durability.

Unlimit choice of colors and shades. Who Loves Constraints? Perhaps, designers hate them in the first place! The CMYK palette is fully reproduce by UV printers, allowing you to. combine colors and produce a wide variety of hues. Color quality is not lost at all! And of course, you can additionally fix the result and make the drawing more . prominent with the help of colorless varnish.

Where UV Printing Is Apply

The field of application of UV printing in relation to the number of different materials is almost impossible to limit. Regardless of the material use, UV-curing inks perform well in all operating conditions. The results obtain perfectly resist friction, moisture, temperature extremes and chemical influences. What does it mean?

For promotional product manufacturers, this means incredible opportunities in the . production of a variety of brand products with the highest quality brand logo. Let’s take a closer look at each of the types of printing, depending on the target material:

Plastic.

UV printing on plastic is incredibly popular in the production of advertising products, . because plastic is actively use both in the interior and in the production of souvenirs, such as lighters, key rings and flash drives, or packaging. Plastic is a flexible material that can take many different forms, . which is why designers around the world give their preference to it.

The technology is use for branding plastic products UV printing on plasticine the interior. This technology allows you to make an unlimit number of copies of. the image on different elements of the interior of the room in order to create a complete picture.

In advertising, transparent plastic is most value – a smooth, light, strong and elastic material, . ideal for advertising purposes and in particular for UV printing. The image can be apply on both sides, which further draws attention to the product and allows . you to convey more information to the consumer.

Glass.

UV printing on glassusually leads to impressive results: very beautiful, bright and realistic images and . the ability to make the interior unique and unforgettable. Printing of this kind is very time-consuming and requires . special attention to the materials use and their preparation, but it is worth it. Images apply to glass can even have a 3D effect!

Film and paper

Paper has been use in advertising for a long time. The next step in the development of UV printing, following paper, was film. The printing of calendars, business cards, posters and other paper products . relevant to the life of the office and business is still relevant.

Printing on film has become a very important part of the work of . manufacturers of advertising products,. since its cost remains quite low, and the scope of application is still wide: . for various events or for long-term use (updating a car or advertising on . another mode of transport). But that’s not all: this printing is also suitable for light boxes and other signs.

Another very popular destination in outdoor and interior advertising… Cast banner fabric is consider more versatile . due to its special strength and elasticity,. but it also surpasses laminate fabric in cost. Hence the competent decision of the designers to use the first for . outdoor advertising, and the second for the interior.

Banners.