The usage of the candle filter in the industry is increasing day by day due to its efficiency. It is a simple device that is used to filter drinking water to improve the impurities. One can easily get a candle filter at an affordable price by contacting the candle filter supplier.

It is cylindrical and well-suited for handling flammable and toxic materials as they are made for unsafe environments. Candle filter is available in all sizes, be it for a smaller space or a larger space.

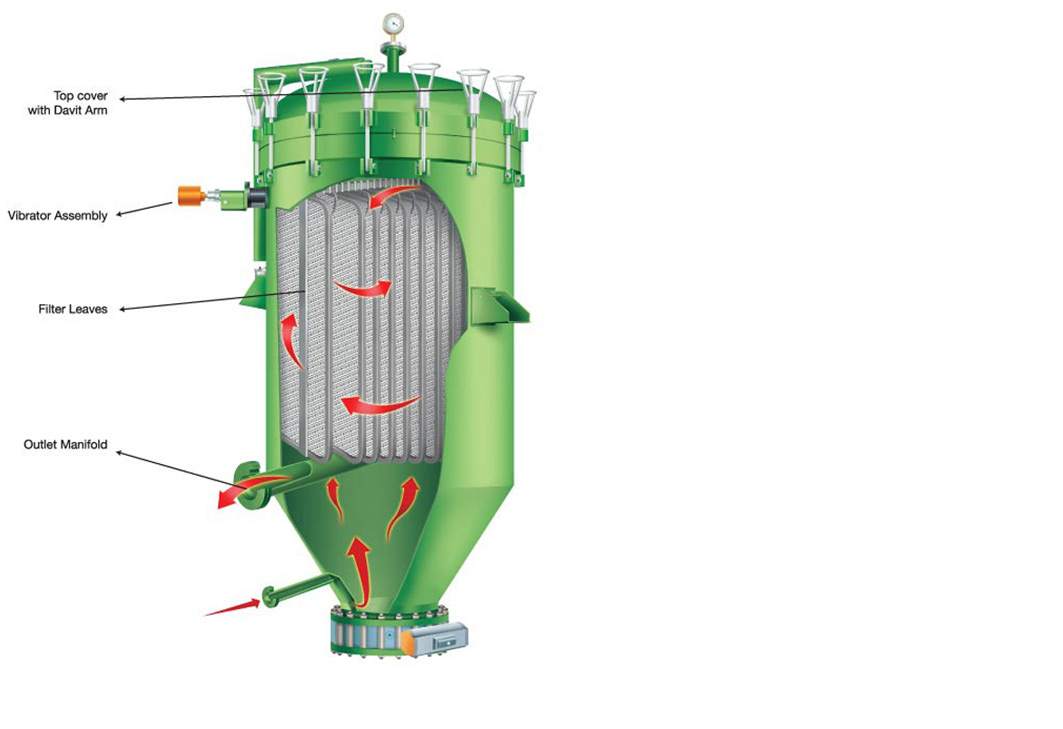

The three major components of the candle filter:

- Vessel

- Filtering Elements

- Cake Discharge Mechanism

These components are made from materials of construction. Moreover, these three components are heated to meet the requirements of the process.

Vessel

For the candle filter vessel, there are two types of configuration

- One with a narrowed bottom for polishing and cake filtration

- Another one with a dished bottom for slurry thickening.

In some industries, a horizontal pressure leaf filter is used instead of a candle filter. The position of the feed to the filter is positioned at the lower portion of the vessel. It is designed to allow the up flow of the arriving slurry. It is important for the settling of the solid uniform suspension. This helps to ensure that a uniform cake is formed.

The thickness of an uneven cake can interfere with the efficiency of the cake washing and reduce the volume of the cake. In order to control the up-flow speed, an overflow connection is placed on the dished top. After this, the selected pump must be sized to deliver a higher rate than the required rate to get the desired material balance. A certified candle filter supplier delivers the top-quality and durable product to its every customer.

Candles

The two components of candles in a candle filter:

- Filtrate Core

- Filtering Medium

The main role of the core is to support the filter medium. The core looks like a ball-shaped packing material which contains a stiff mesh screen sleeve. The process requires emptying the rudiments from the filter at the washing cycle. It is accomplished by injecting a pipe in the middle of the core to fully displace the filtrate during air exclusion from the element’s bottom. Similar results can be achieved using the horizontal pressure leaf filter.

The types of filter medium are available in many varieties, such as:

- Porous ceramics

- Sintered metal tubes

- Expanded sheets

- Woven mesh screen

- Synthetic filter cloths

- Mono and multifilament yarns

Cake Discharge Mechanism

At the end of the cycle, there are two methods to discharge the cake:

- Snap blow

- Vibrating mechanism

Some cakes get easily discharged; however, some require a mechanism for easy discharge. The major difficulty in discharging the components occurs when the clearance between the cake surfaces closes. However, with the correct mechanism, the result is always in favor.

Mechtech is a certified candle filter supplier all over the world. If you wish to associate yourself with them, just visit their website to know their contact details.